API标准止回阀完全按照美国标准设计制造,结构美观、先进。 美标止回阀是依靠介质本身的流动而自动启闭阀瓣,用于防止介质倒流的阀门,又称止回阀、止回阀、逆流阀,其主要作用是 防止介质倒流,防止泵和驱动电机反转,以及容器介质的释放。

性能参数:

|

项目名 |

范围 |

|||||

|

公称压力PN(MPa) |

150LB |

300LB |

600LB |

900LB |

1500LB |

2500LB |

|

2.0 |

5.0 |

10.0 |

15.0 |

25.0 |

42.0 |

|

|

壳体强度试验压力 |

常温下公称压力的1.5倍 |

|||||

|

高压密封试验压力 |

常温下公称压力的1.1倍 |

|||||

|

常温工作压力 |

按ASME B16.34压力和温度等级 |

|||||

产品规格:

|

Design standards |

Structure length |

Flange connection size |

Test and inspection |

Pressure and temperature reference |

|

API6D/ASME B16.34 |

ASME B16.10 |

ASME B16.5 |

API598/API6D |

ASME B16.34 |

主要零件材质:

|

零件名称 |

材料名称 |

|||||

|

Body |

A216 WCB |

A217 WC6 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

|

cap |

A216 WCB |

A217 WC6 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

|

Valve plate |

A216 WCB |

A217 WC6 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

|

Sealing surface |

13Cr/STL |

STL |

Body / STL |

Body / STL |

Body / STL |

Body / STL |

|

Valve shaft |

A182 F6a |

A182 F11 |

A182 F304 |

A182 F316 |

A182 F304L |

A182 F316L |

|

Gasket |

Flexible graphite |

Flexible graphite |

Flexible graphite |

Flexible graphite |

Flexible graphite |

Flexible graphite |

|

bolt |

A193 B7 |

A193 B16 |

A193 B8 |

A193 B8M |

A193 B8 |

A193 B8M |

|

Nut |

A194 2H |

A194 4 |

A194 8 |

A194 8M |

A194 8 |

A194 8M |

|

Operating temperature |

-29~425℃ |

-29~540℃ |

-46~425℃ |

-46~425℃ |

-46~425℃ |

-46~425℃ |

|

Suitable media |

steam |

steam |

Weak corrosive |

Weak corrosive |

Weak corrosive |

Weak corrosive |

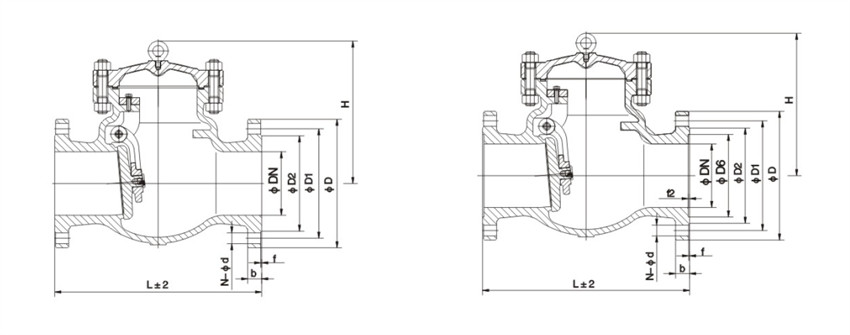

主要外形及连接尺寸:

|

公称通径 |

尺寸 |

||||||||

|

m |

in |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

H |

|

H44H-150Lb |

|||||||||

|

50 |

2 |

203 |

152 |

120.5 |

92 |

16 |

1.6 |

4-19 |

180 |

|

80 |

3 |

241 |

192 |

152.5 |

127 |

19 |

1.6 |

4-19 |

190 |

|

100 |

4 |

297 |

229 |

190.5 |

157 |

24 |

1.6 |

8-19 |

203 |

|

125 |

5 |

330 |

254 |

216 |

186 |

24 |

1.6 |

8-22 |

229 |

|

150 |

6 |

356 |

279 |

241.5 |

216 |

26 |

1.6 |

8-22 |

257 |

|

200 |

8 |

495 |

342 |

298.5 |

270 |

29 |

1.6 |

8-22 |

292 |

|

250 |

10 |

622 |

406 |

362 |

324 |

31 |

1.6 |

12-25 |

355 |

|

300 |

12 |

698 |

483 |

432 |

381 |

32 |

1.6 |

12-25 |

396 |

|

H44H-300Lb |

|||||||||

|

50 |

2 |

267 |

165 |

127 |

92 |

23 |

1.6 |

8-19 |

178 |

|

80 |

3 |

318 |

210 |

168.5 |

127 |

29 |

1.6 |

8-22 |

216 |

|

100 |

4 |

356 |

254 |

200 |

157 |

32 |

1.6 |

8-22 |

241 |

|

125 |

5 |

400 |

279 |

235 |

186 |

35 |

1.6 |

8-22 |

267 |

|

150 |

6 |

444 |

318 |

270 |

216 |

37 |

1.6 |

12-22 |

305 |

|

200 |

8 |

533 |

381 |

330 |

270 |

42 |

1.6 |

12-25 |

368 |

|

250 |

10 |

622 |

445 |

387 |

324 |

48 |

1.6 |

16-29 |

394 |

|

300 |

12 |

711 |

521 |

451 |

381 |

51 |

1.6 |

16-32 |

445 |

|

H44H-600Lb |

|||||||||

|

50 |

2 |

295 |

165 |

127 |

92 |

33 |

6.4 |

8-19 |

203 |

|

80 |

3 |

359 |

210 |

168 |

127 |

36 |

6.4 |

8-22 |

235 |

|

100 |

4 |

435 |

273 |

216 |

157 |

45 |

6.4 |

8-25 |

286 |

|

125 |

5 |

511 |

330 |

266.5 |

186 |

52 |

6.4 |

8-29 |

292 |

|

150 |

6 |

562 |

356 |

292 |

216 |

55 |

6.4 |

12-29 |

330 |

|

200 |

8 |

664 |

419 |

349 |

270 |

63 |

6.4 |

12-32 |

381 |

|

250 |

10 |

791 |

510 |

432 |

324 |

71 |

6.4 |

16-35 |

457 |

|

300 |

12 |

842 |

559 |

489 |

381 |

74 |

6.4 |

20-35 |

584 |

结构图: